Most facility leaders accept wind turbines. They reject the disruption that comes with installing them. When a project appears to involve weeks of heavy civil work, crane days, and blocked parking, the idea often dies in the meeting room. The challenge has never been whether wind works; it’s whether the process of putting it up fits the rhythm of a school, a retail lot, or a public yard.

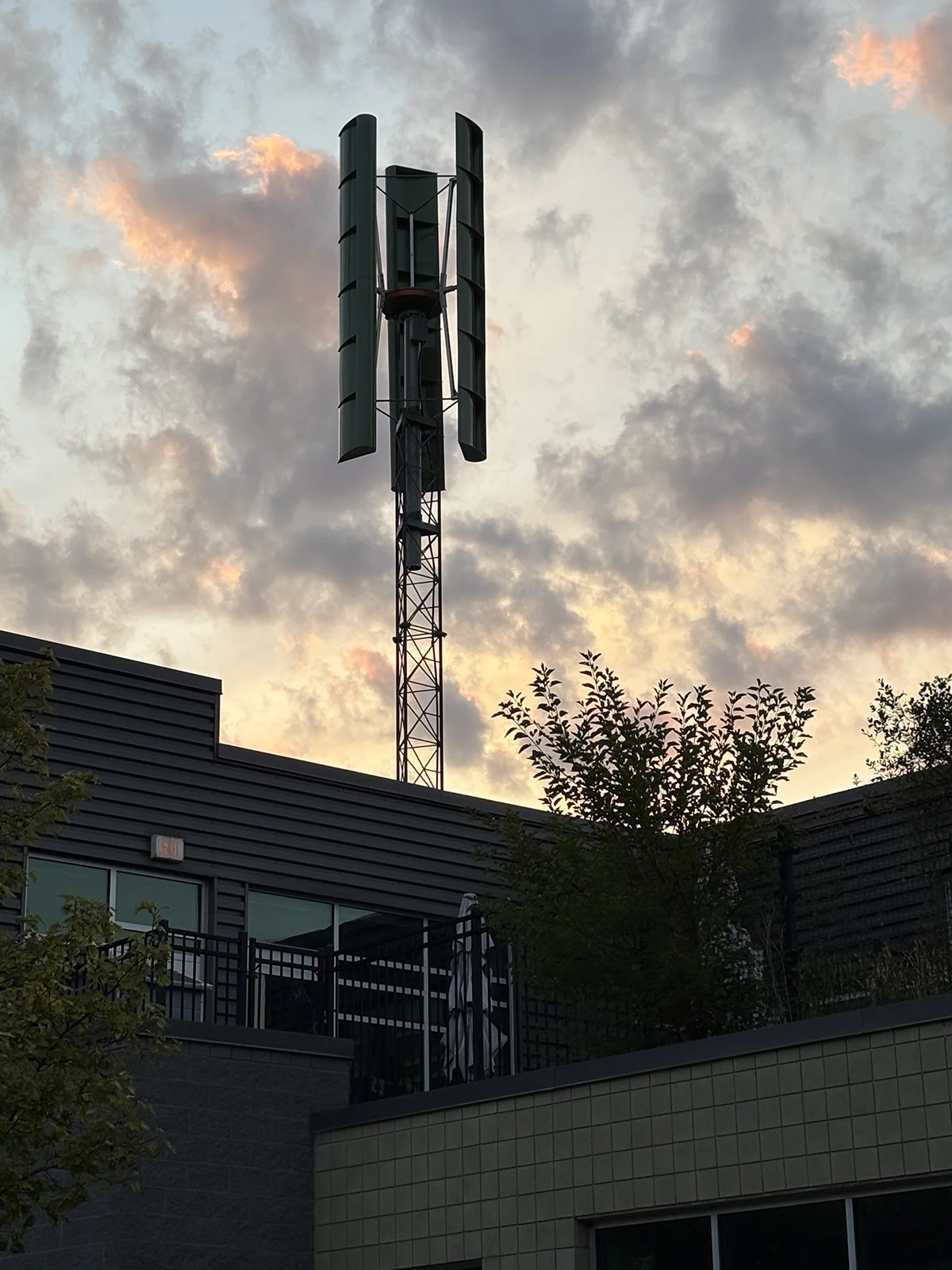

Mundo-Power’s fixed 6.25 kW vertical wind turbine generator was designed to answer that question. The installation happens in six contained steps. No long pauses for curing concrete. No multi-day crane plans. No risky lifts at height. Just a short, predictable sequence that brings the first power without turning a site upside down.

Why Do Installs So Often Stall

Community and commercial sites have been pursuing wind energy for decades. The performance is proven. The pain comes before every turn of the blades. Large concrete foundations mean weeks of idle time. Tower and rotor lifts for industrial wind turbines require large cranes, certified crews, and favorable weather conditions. Each added stage introduces a place for the schedule to slip, a chance for neighbors to complain, or a new bill to pay.

Managers know the feeling: your calendar is already packed, and now you’re being asked to plan around three weeks of construction, hoping the weather cooperates. That’s the reality that has slowed the adoption of small and mid-scale wind.

- Locate: Imagine crews arriving not with excavation gear but with survey paint and a small piling rig. Utility locates are done, marks go on the ground, and you’re ready to set steel the same week. There are no long permit delays associated with tower height or noise, as the unit is modest in scale and designed to be quiet. The start feels less like a construction site and more like routine site prep.

- Screw Pile: The foundation is where most projects lose weeks. Traditional turbines require a reinforced concrete pad that must be placed and allowed to cure before it can be used. Mundo-Power’s turbine skips that. A steel screw pile is driven into the ground and is immediately ready to carry a load. By the end of the day, the foundation is complete, with no rebar, no trucks, and no downtime.

- Base Plate: After the pile is set, a prefabricated base plate is bolted into place. Level it, torque it, and the site is ready for the tower. Compare that to aligning anchor bolts in a cured foundation and hoping nothing shifted. With Mundo’s design, there are no surprises, no rework, and no extra visits from engineers.

- Tower Base: This is where most installs diverge. A horizontal turbine requires cranes to stand tower sections vertically, with each lift subject to wind conditions. One nasty gust, and the crew is back tomorrow. Mundo’s tilt-up tower avoids all of it. Sections are bolted together on the ground, safely and quickly. The hinge at the base does most of the work.

- Turbine Assembly at Grade: Bolting blades onto a hub at 80 feet is slow, expensive, and risky. Mundo’s vertical-axis wind turbine for sale is assembled at grade. Blades, hub, and generator connections are made within arm’s reach. There’s no yaw motor to align, no gearbox perched on top of a mast. The design has fewer moving parts and a simpler fit-up, which shortens the path to commissioning.

- Tilt-Up Raise: With everything built at ground level, the final rise is a single clean step. A hydraulic ram or winch tilts the tower into place, locks it, and the turbine is standing. Cables are landed, checks are run, and the system is live. For many sites, that means first power the same day the tower goes up.

Which Sequence Fits Your Site?

Think about your options side by side for vertical axis wind turbine for sale:

- A screw pile foundation installed in a day, or weeks waiting on concrete.

- A tower bolted together at grade, or multiple crane lifts at height.

- A quiet vertical-axis rotor assembled within arm’s reach, or blades swung by crane in tight weather windows.

- A tilt-up raise in hours, or a rolling crane plan that ties up your site.

Both approaches result in a turbine that generates power. Only one fits the realities of schools, retail lots, and municipal yards.

What This Means for You

If you manage a campus, a shopping center, or a public facility, the numbers matter, but the issues of the calendar matter more. A six-step install that takes hours, operates quietly around people, and requires service only every few years is the path that makes sense.

So ask yourself the following questions:

- Can my site absorb weeks of construction?

- Or do I need a project that fits into days?

- Do I want to explain crane days to neighbors?

- Or would I rather point to a system that went up quietly and is already producing?

Six Steps to a Simpler Project

The answer is not abstract. It’s six specific steps: locate, screw pile, base plate, tower base, turbine assembly at grade, and tilt-up raise. That’s the process that gets you to first power without the construction saga.

If your targets are simple — predictable install, quiet operation, long service life — then the path is simple too. Define your limits and ask Mundo-Power for a scoped, six-step plan that aligns with them.